In today’s fashion and apparel industry, shirt printing plays a huge role in brand identity. Whether you are a startup launching your first collection or an established brand expanding into new categories, the printing method you choose will directly influence how your products look, feel, and sell.

With so many t-shirt printing techniques available, it can be confusing to decide which option works best for your business. Some methods offer vibrant colors but require higher order quantities, while others are cost-effective for small batches but may not be as durable.

At Argus Apparel, we specialize in providing custom shirt printing solutions for startups, private labels, and fashion brands. From screen printing to DTG, sublimation, heat transfer, vinyl, and embroidery, our expertise ensures that your designs stand out in quality and style.

This guide covers the types of shirt printing available in 2026, their pros and cons, and tips to help you choose the best method for your brand.

What Is Shirt Printing & Why Does It Matter?

In today’s competitive fashion market, where streetwear brands, activewear companies, luxury labels, and print-on-demand businesses are all competing for consumer attention, the right t-shirt printing technique can make your brand stand out. Whether it’s creating a premium finish for a luxury line or an affordable, vibrant print for promotional wear, shirt printing is the bridge between your design vision and a finished product that sells.

Shirt printing is the process of transferring artwork, text, or branding elements onto t-shirts and other garments using different techniques such as screen printing, DTG, or sublimation. While it may seem like a design choice, the printing method plays a much bigger role in the success of an apparel brand. It is not just about creating a stylish look, it is about building recognition, trust, and value for your business.

For clothing businesses, the shirt printing method you choose impacts three critical areas:

1. Brand Identity

A well-printed shirt instantly elevates your brand image. The quality of the print communicates professionalism, diligence, and the overall standard of your products. A bold, vibrant logo or a subtle premium finish can set the tone for how customers perceive your brand.

2. Customer Experience

Printing directly influences how a customer feels about your product. A soft-to-touch print that lasts after several washes creates a sense of reliability, while a print that cracks or fades quickly can harm your reputation. The print’s durability, vibrancy, and texture all shape customer satisfaction.

3. Business Growth

The printing method affects your scalability and profitability. For example, some methods are ideal for large wholesale orders, while others are cost-effective for small runs and startups. Choosing the right process helps you balance expenses, maintain consistent quality, and grow your apparel line strategically.

Popular Types of Shirt Printing

The world of t-shirt printing techniques has expanded significantly in recent years, offering apparel brands more options than ever before. From traditional methods like screen printing to advanced digital solutions like DTG and sublimation, each approach comes with unique advantages depending on your order size, fabric choice, and design complexity.

Understanding these shirt printing methods is key for startups, streetwear labels, sportswear brands, and print-on-demand businesses aiming to make the right decision for their products. Below, we’ll explore the most popular t-shirt printing methods in 2026, covering how each works, its strengths, and limitations, and which apparel businesses benefit most.

1. Screen Printing

Screen printing is one of the oldest and most widely used custom t-shirt printing methods. It uses mesh screens and ink to create bold, long-lasting designs. Each color requires its own screen, which makes the process best suited for simple, high-impact graphics.

How it works

A stencil of the design is created on a mesh screen. Ink is then pushed through the screen onto the fabric using a squeegee. For multi-color prints, the process is repeated with different screens.

Pros

- Produces durable, vibrant colors.

- Extremely cost-effective for large runs.

- Works well on cotton and cotton-blend fabrics.

Cons

- Not suitable for highly detailed, multi-color artwork.

- Higher upfront cost due to setup and screen preparation.

Best for: Wholesale orders, promotional T-shirts, bold logos, and designs with limited color palettes.

Cost considerations: The per-unit cost drops significantly with higher volumes, but small batches can be expensive due to setup requirements.

2. Direct-to-Garment (DTG) Printing

DTG is a digital shirt printing method that allows highly detailed, colorful designs to be printed directly onto fabric using specialized inkjet printers.

How it works

Much like a desktop printer, DTG sprays water-based inks directly onto the garment. The inks are absorbed by the fibers, producing smooth, photo-quality prints.

Pros

- Ideal for detailed, full-color designs.

- Low minimum order quantity (MOQ).

- Produces a soft, lightweight print.

Cons

- Not as durable as screen printing.

- Slower production for bulk orders.

Best for: Startups testing designs, print-on-demand businesses, and brands needing small batches with intricate details.

Cost considerations: Affordable for small runs; however, per-unit costs increase in bulk compared to traditional methods.

3. Sublimation Printing

Sublimation is a high-quality digital process that uses heat to infuse dye into polyester fabrics, creating permanent, full-color designs.

How it works

Designs are printed onto special sublimation paper using sublimation inks. Under high heat, the ink turns into gas and bonds with the polyester fibers, resulting in a seamless, durable finish.

Pros

- Unlimited colors with no cracking, peeling, or fading.

- Perfect for all-over and edge-to-edge prints.

- Lightweight, breathable designs ideal for sportswear.

Cons

- Works only on polyester or poly-blend fabrics.

- Not compatible with 100% cotton.

Best for: Activewear, sportswear, and fashion brands offering all-over custom T-shirts.

Cost considerations: Cost-effective for medium-sized orders but limited to polyester-based garments.

Learn more: Sublimation Printing Services

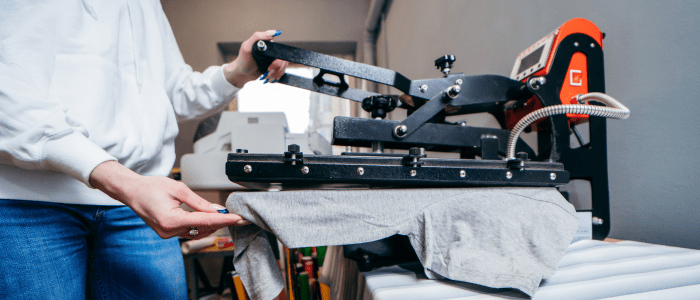

4. Heat Transfer Printing

Heat transfer involves printing a design onto transfer paper or film and then applying it to fabric using heat and pressure.

How it works

The design is first printed with special inks onto a transfer sheet. A heat press machine then transfers the print from the sheet to the shirt.

Pros

- Produces vibrant, full-color prints.

- Flexible for small batches and customization.

- Quick turnaround for on-demand printing.

Cons

- Prints may peel, fade, or crack over time.

- The finished design can feel less breathable on the fabric.

Best for: Promotional apparel, small-run collections, and brands testing new designs.

Cost considerations: Low setup cost, making it suitable for small orders, but not ideal for long-term durability.

5. Vinyl Printing

Vinyl printing uses heat to press cut-out vinyl designs directly onto fabric. It is widely used for logos, names, and numbers.

How it works

A plotter machine cuts designs from colored vinyl sheets. The vinyl is then applied to the shirt using a heat press.

Pros

- Durable, bold prints with excellent color consistency.

- Great for lettering, logos, and sports numbers.

- Works on most fabrics.

Cons

- Limited design complexity (not suitable for detailed graphics).

- Adds a slightly heavier feel to the garment.

Best for: Sports jerseys, team uniforms, and custom lettering.

Cost considerations: Cost-effective for small runs but less practical for detailed or large-scale designs.

6. Discharge Printing

Discharge printing is a specialty method where the original dye of the fabric is removed and replaced with new pigment, leaving a soft, breathable print.

How it works

A discharge agent is applied to the shirt, bleaching out the fabric’s original dye. New pigment is then added, bonding with the fabric fibers.

Pros

- Produces a vintage, soft-to-touch look.

- Ideal for dark shirts and cotton fabrics.

- Long-lasting, breathable finish.

Cons

- Limited color options compared to other methods.

- Works only on 100% cotton.

Best for: Streetwear brands, vintage-inspired collections, and apparel seeking a soft, washed look.

Cost considerations: Moderate cost, requiring precise handling and fabric compatibility.

7. Embroidery as an Alternative

While not a printing method, embroidery is a premium alternative for apparel branding. Instead of ink, designs are stitched directly onto garments, giving a texture, high-quality finish.

Pros

- Premium, long-lasting appearance.

- Excellent for logos, uniforms, and luxury apparel.

- Durable and resistant to fading.

Cons

- Limited detail for intricate artwork.

- Higher cost compared to most printing techniques.

Best for: Polo shirts, uniforms, corporate wear, and high-end fashion.

Explore more: Custom Embroidery Services

Comparison Table

| Printing Method | Best For | Durability | Cost | MOQ |

|---|---|---|---|---|

| Screen Printing | Bulk orders, bold logos | High | Low (bulk) | High |

| DTG Printing | Small runs, detailed designs | Medium | Medium | Low |

| Sublimation | Sportswear, all-over prints | High | Medium | Medium |

| Heat Transfer | Small batches, promo t-shirts | Medium | Low | Low |

| Vinyl Printing | Sports jerseys, numbers/logos | High | Medium | Low |

| Discharge Printing | Vintage streetwear, cotton tees | High | Medium | Medium |

| Embroidery | Premium branding, polos, uniforms | Very High | High | Low/Medium |

How to Choose the Right Shirt Printing Method for Your Brand

Selecting the best t-shirt printing method is one of the most important decisions for any apparel business. The right choice not only impacts how your products look and feel but also influences your production costs, scalability, and how customers perceive your brand. There isn’t a one-size-fits-all answer—it depends on your unique goals, budget, fabric selection, and target market.

Here are the main factors to consider when deciding on a shirt printing method:

1. Order Size

Your production volume plays a big role in determining the right technique.

- Large wholesale or bulk orders: Screen Printing is the most cost-effective because setup costs spread across many units, and prints remain durable.

- Small batches or startups: DTG or Heat Transfer Printing are better since they don’t require high minimums and allow you to experiment without overstocking.

2. Budget

Different methods vary in cost and setup requirements.

- Tight budget / evaluating a new line: Heat Transfer or Vinyl Printing can help you start small without high upfront investment.

- Premium investment: If your focus is long-term quality and high perceived value, Embroidery or Sublimation Printing will deliver a refined finish that appeals to luxury or activewear markets.

3. Fabric Type

The fabric composition often limits or guides which method you can use.

- Polyester or poly-blends: Sublimation Printing works best since the dye bonds directly with the fibers.

- Cotton or cotton blends: Screen Printing, DTG, or Discharge Printing give excellent results with vibrant colors and durability.

- Blended fabrics: Depending on the percentage mix, Heat Transfer or Vinyl may be used effectively.

4. Design Complexity

The type of artwork you want to print should guide your choice.

- Detailed, photo-like artwork with gradients or multiple colors: DTG is the ideal method, as it can capture fine detail.

- Bold logos, slogans, or sports numbers: Screen Printing or Vinyl provide crisp, durable results with solid colors.

5. Brand Positioning

Your printing method should align with how you want your brand to be perceived.

- Premium or luxury fashion brands: Embroidery communicates sophistication and lasting quality.

- Streetwear and casualwear: Discharge Printing and Screen Printing create bold, urban-inspired designs.

- Sportswear and activewear: Sublimation Printing offers lightweight, breathable all-over designs perfect for athletic use.

- Promotional or fast-moving products: Heat Transfer allows quick, affordable production for campaigns and events.

Making the Right Decision

By weighing these factors, order size, budget, fabric type, design complexity, and brand positioning, you can identify the shirt printing method that best supports your business goals. Startups may experiment with flexible, low-MOQ methods like DTG or heat transfer, while established brands scaling into wholesale may find screen printing or sublimation more efficient.

The key is to balance cost, quality, and brand image, ensuring that every printed shirt not only represents your design but also strengthens your brand identity in a competitive apparel market.

You can also check out our blog on: How to start a print-on-demand business.

Printing with Argus Apparel

At Argus Apparel, we understand that every clothing brand has unique needs. That’s why we offer multiple custom shirt printing methods under one roof. Whether you’re a startup evaluating a small batch or a retailer planning bulk orders, our services include:

- Low MOQs for new brands.

- Access to all major T-shirt printing techniques.

- Premium quality assurance for long-lasting prints.

- End-to-end support from design to manufacturing.

Check out our Custom T-Shirt Manufacturing Services to start your journey.

Ready to bring your designs to life? Partner with Argus Apparel for expert custom printing solutions tailored to your brand.